Technology

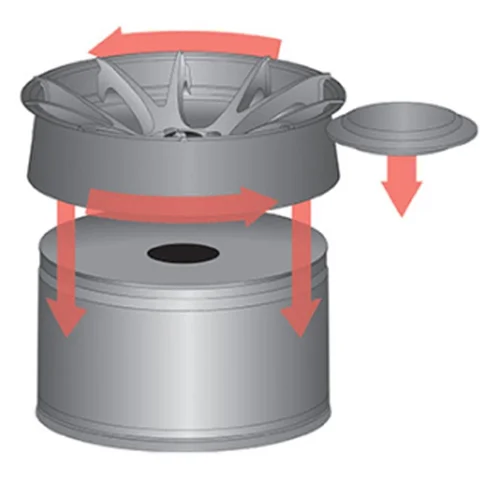

Step 1

Each Forgestar wheel starts as a specially designed blank made from high-grade aluminum, which is heated and spun to shape it into a wheel.

Step 2

The blank is then placed into a machine with hydraulic rollers that apply heat and pressure to form the wheel's barrel to the correct sizing specifications.

Step 3

The aluminum is repeatedly stretched and compressed as the rollers extend outward on the barrel, reinforcing the wheel's grain structure.

Flow-Formed Wheel Benefits

- Lighter - Forgestar flow-formed wheels are lighter than traditional cast wheels, optimizing acceleration, handling, and braking to make your car more agile and engaging.

- Stronger -With an optimized molecular grain structure, flow-formed wheels have higher tensile strength and improved impact capacity to withstand the demands of high-performance driving.

- Customizable - Forgestar offers extensive customization capabilities, allowing you to build your wheels your way and bring your dream car to life.

Design Sketches

Every Forgestar wheel begins as a hand-drawn sketch, allowing our team of engineers to unleash their creativity and incorporate distinctive design elements to ensure every wheel we create is a true work of art.

Purpose Built Performance

The sketch is then built in CAD software where our engineers modify each wheel design to ensure they are optimized for strength, fatigue-resistance, reduced rotational mass, and competitive capabilities.

Rigorous Testing

The wheel design is tested with simulation programs such as Finite Element Analysis (FEA) to test structural integrity, along with impact testing, cornering fatigue testing, and radial fatigue testing to exceed industry standards and maximize performance